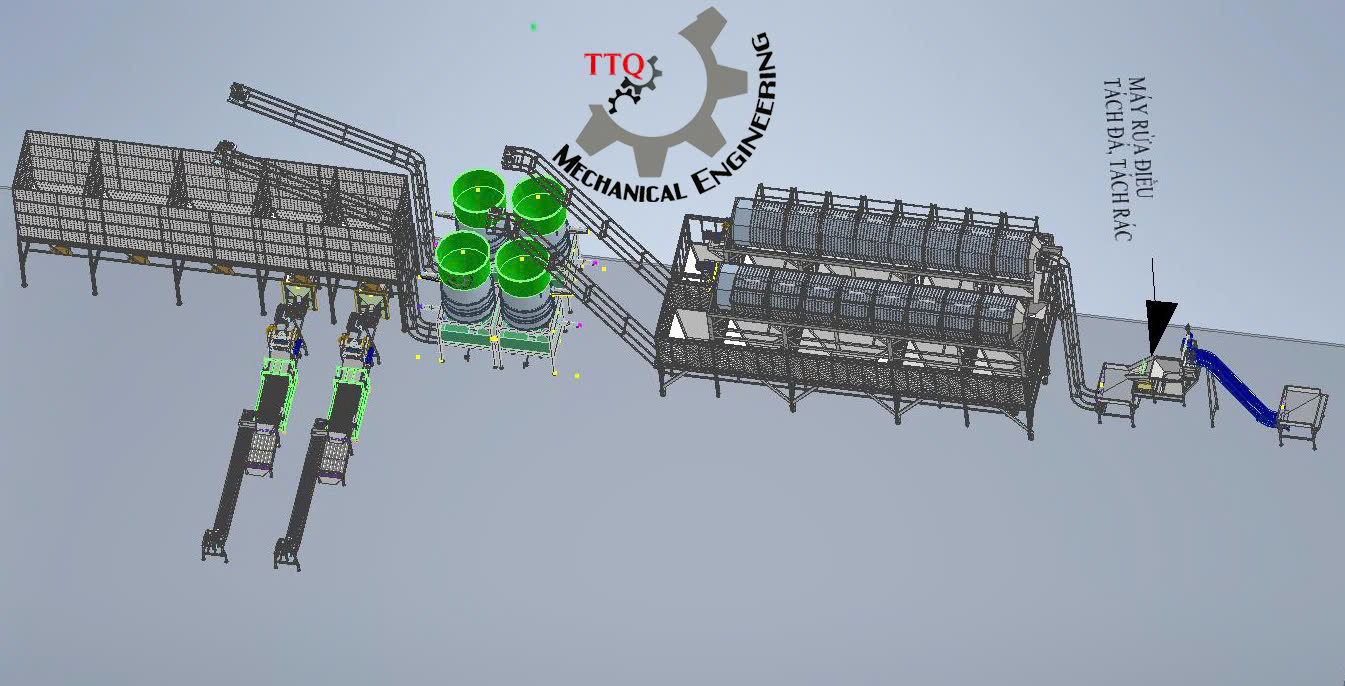

Cashew Processing Plant – Complete Cashew Nut Processing Line for Export Quality

Discover a complete cashew processing plant equipped with modern machines, stable output, and export-quality kernels. Watch a practical factory operation video from our African customer.

Cashew Processing Plant – Inside a Modern Cashew Nut Processing Line

In recent years, Vietnam has become one of the leading suppliers of cashew processing plants for Africa, Asia, and emerging markets. With increasing demand for export-quality cashew kernels, processors are now focusing on complete, stable, and automated cashew nut processing lines rather than standalone machines.

In this article, we introduce a cashew processing plant of our customer in Africa, explain the full processing flow, and share a practical factory operation video to help buyers clearly understand how a modern cashew plant operates in practice.

Why Invest in a Complete Cashew Processing Plant?

For cashew processors, especially those targeting export markets, a complete processing plant brings clear advantages:

✅ Stable kernel quality and uniform appearance

✅ Higher whole kernel rate

✅ Reduced labor dependency

✅ Easier quality control and food safety compliance

✅ Scalable capacity for future expansion

Instead of buying machines separately, a full cashew processing plant ensures that all stages are synchronized, reducing loss and improving efficiency.

Cashew Processing Flow – From Raw Cashew to White Kernels

A modern cashew processing plant typically includes the following stages:

1. Raw Cashew Cleaning & Grading

Raw cashew nuts are cleaned to remove stones, dust, and impurities, then graded by size to ensure stable processing in later stages.

Cashew-processing-plant-cleaning-process

2. Steaming

Steaming softens the shell and prepares the nuts for shelling while protecting the kernel inside. This step is critical for maintaining kernel integrity.

Cashew-processing-plant-steaming-process

3. Cashew Shelling

Shelling machines crack the hard shell with high accuracy and low breakage rate, producing whole kernels suitable for export standards.

cashew-processing-plant-shelling-machine

4. Kernel Drying

Kernels are dried to the required moisture level, making it easier to peel the testa (skin) and improving shelf life.

Cashew-processing-plant-kernel-drying-system

5. Humidification & Peeling

After conditioning, the thin skin is removed efficiently, resulting in clean white kernels.

Cashew-processing-plant-peeling-machine

6. Color Sorting & Manual Inspection

Color sorting machines remove defective kernels, followed by manual inspection to meet strict quality requirements.

7. Grading & Vacuum Packing

Finished kernels are graded and vacuum packed to preserve freshness during storage and transportation.

Cashew-processing-plant-vacuum-packing-line

Watch a Cashew Processing Plant Operation Video 🎥

To help buyers clearly understand the practical operation, we share a factory operation video recorded at our customer’s cashew processing plant in Africa, where machines supplied by TTQ Vietnam Machines are in use.

👉 Watch the video here:

YouTube: Cashew Processing Plant – From Raw Nuts to Export-Quality Kernels

This video shows:

-

Practical machine operation during processing

-

Practical processing flow inside the factory

-

Kernel output quality at each stage

It is especially useful for buyers who want to evaluate practical production capability before investment.

Cashew Processing Plant Solutions from Vietnam – Why Buyers Choose TTQ

At TTQ Vietnam Machines, we provide complete cashew processing plant solutions, not just individual machines.

Our advantages include:

✔ Practical designs based on factory application experience

✔ Flexible capacity: small, medium & industrial scale

✔ Stable performance for African and tropical conditions

✔ Technical support, layout advice & installation guidance

Each cashew processing plant can be customized based on:

-

Raw cashew size

-

Desired capacity (kg/hour or tons/day)

-

Labor availability

-

Budget and expansion plan

Please click to discover more >> complete cashew nut processing lines << manufactured in Viet Nam.

Who Is This Cashew Processing Plant Suitable For?

This solution is ideal for:

-

Cashew processors starting a new factory

-

Existing factories upgrading from semi-manual to automated

-

Export-oriented processors targeting EU, US, or Middle East markets

-

Investors seeking long-term, stable cashew processing projects

Looking for a Reliable Cashew Processing Plant?

If you are planning to invest in a cashew processing plant or looking for a complete cashew nut processing line, we recommend starting with practical factory solutions and practical operation videos, not just brochures.

📩 Contact TTQ Vietnam Machines to receive:

-

Plant layout proposal

-

Machine configuration suggestion

-

Video references of similar customer projects

👉 Don’t forget to watch our cashew processing plant operation video on YouTube to better understand the practical processing flow before making your decision.

TTQ INDUSTRIAL EQUIPMENT MANUFACTURE COMPANY LIMITED

Office Address: 125C, Street 14, Ben Cat Quarter, Phuoc Binh Ward, Thu Duc City, Ho Chi Minh, VN

Tel: +84-28 62763105 ; +84-918 077 948

Workshop Address: 215 Bung Ong Thoan Street, Tang Nhon Phu B Ward, Thu Duc City, Ho Chi Minh, VN

Mobile/Whatsapp/Wechat:

- +84-918077948 (Mr Rod)

- +84-933001235 (Ms Hanna)

- +84-788545905 (Ms Mary)

Email: info@ttqvietnammachines.com

Homepage: ttqvietnammachines.com

main.comment_read_more